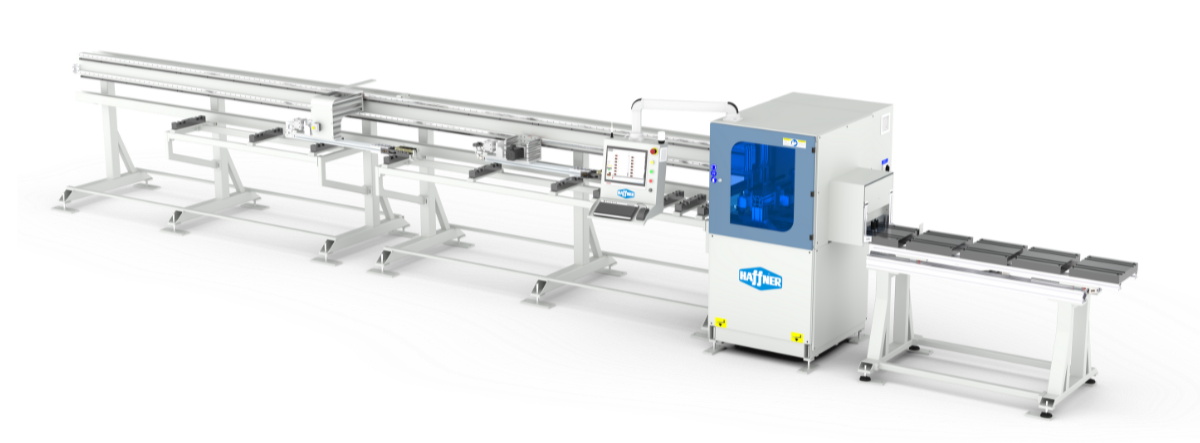

Fresh Off the Line: The New TA-144/30 Automatic Aluminum Wedge Cutting Saw

Innovative Double Pusher Track for Maximum Efficiency

The TA-144/30 Automatic Aluminum Wedge Cutting Saw is a cutting-edge solution for manufacturers seeking precision, speed, and automation in aluminum wedge cutting. As the new step one in the AUTOSCREEN™ product cell, it sets the foundation for a fully automated screen frame production process.

With its groundbreaking double pusher track design, the TA-144/30 can cut four pieces at once—two at one length and two at another—delivering a complete frame in a single operation. It delivers consistent, accurate cuts at high speed, ensuring that every subsequent step in the AUTOSCREEN workflow operates seamlessly.

For fenestration manufacturers, this means:

Improved Efficiency: Automating the initial cutting step reduces manual handling and accelerates production timelines.

Enhanced Accuracy: Precision cutting minimizes errors, ensuring a perfect fit and alignment for screen frames.

Cost Savings: Streamlined operations reduce labor costs and material waste.

Scalability: Ideal for high-volume production environments, supporting growth without compromising quality.

The TA-144/30 has become the starting point for a smarter, more integrated approach to screen frame manufacturing. Keep reading to learn how this system will optimize and boost your current production line.

Q&A with Haffner Machinery

What is the TA-144/30, and why should I consider it?

The TA 144/30 is an automatic aluminum wedge cutting saw designed for precision and efficiency using a ball screw material infeed system. If you manufacture aluminum frames, this machine helps you cut profiles accurately and consistently, reducing manual labor and improving productivity.

The TA-144/30 is a multi-track saw with limited fabrication capability for window screen frame profiles. This machine features an innovative double pusher track — meaning 2 tracks that allow for 4 pieces to be cut simultaneously. It processes 2 pieces at one length and 2 pieces at another at the same time to create the pieces for a full frame in one go with one operator.

How does the TA-144-30 fit into my production process?

The TA-144/30 is step one of the AUTOSCREEN product cell, which means it’s optimized for a fully automated screen frame manufacturing system. While TA-144/30 is a part of the AUTOSCREEN trio, it can also operate as a standalone unit and seamlessly integrate into your production line. If you’re looking to streamline operations and minimize errors, this saw is a perfect fit.

Will this machine save me time and money?

The TA-144/30 saves time and money in multiple ways. By automating wedge cutting:

Cost Efficiency: Lower labor costs and reduced material waste.

Consistency: Every cut meets exact specifications, reducing rework and scrap.

Time Savings: Faster production cycles compared to manual cutting.

By speeding up production, this machine can cut all four profile pieces for a window screen frame in about 15 seconds, increasing throughput for a shift.

Is it easy to operate?

The TA-144/30 is designed for user-friendly operation with automated controls. Combatting the skilled labor shortage, the TA-144/30 only needs one operator to fully function. Minimal training — that the Haffner team will personally walk you through — is required, and safety features ensure a secure working environment.

How does it improve safety on my shop floor?

Automation means less manual handling of sharp materials, which significantly reduces the risk of cuts and repetitive stress injuries from repetitive cutting tasks. By taking over the most physically demanding step, the TA-144/30 helps protect operators from strain and fatigue. Plus, the machine includes protective guards and emergency stop features to keep operators safe during operation.

The TA-144/30 Automatic Aluminum Wedge Cutting Saw establishes a new benchmark for precision and efficiency in fenestration manufacturing. It delivers accurate, repeatable cuts that optimize downstream processes and reduce variability in screen frame assembly.

Its dual-track system enables simultaneous multi-length cutting, significantly increasing throughput while minimizing operator intervention. For manufacturers seeking scalable, high-performance solutions, the TA-144/30 is a critical component in achieving a fully automated, cost-effective production line.

Ready to Take the First Step Toward Full Automation?

Don’t wait to modernize your shop floor. Contact Haffner Machinery to learn how the TA-144/30 can integrate into your production line and transform your workflow.