SAC-850 FAQ: The Smart Solution for Automated Window Assembly

The AUTOSCREEN™ product cell is setting a new standard in automated window assembly for the fenestration industry. And the SAC-850 Mesh/Spline Insertion & Trim machine is now available, optimizing step three of the AUTOSCREEN process. Designed to bridge the gap between smaller and larger screen insertion machines, SAC-850 offers manufacturers a versatile, efficient solution for producing a wide range of window types.

Boosting productivity, optimizing manual labor, and reducing repetitive strain injuries have become key drivers in fenestration manufacturing. SAC-850 provides a solution with reliable, quick, and automated mesh screen and spline insertion.

We sat down with Haffner Machinery’s Product Development Specialist, Tony C., to understand its capabilities, benefits, and how it can transform your window production workflow. If you’re considering automation or upgrading your current equipment, the SAC-850 is engineered to meet the evolving needs of modern window manufacturers.

FAQ with Tony C.

What is SAC-850, and what makes it different from SAC-845 and SAC-855?

SAC-850 is a mid-size automated screen and spline insertion machine designed for the fenestration manufacturing industry. It fills the gap between smaller machines (like SAC-845, ideal for smaller household windows) and larger ones (like SAC-855, suited for sizes up to patio doors). SAC-850 is perfect for companies producing larger windows and doors, but not patio doors, offering a more usable size range for high-volume window manufacturers.

What types of window screens can be processed on SAC-850?

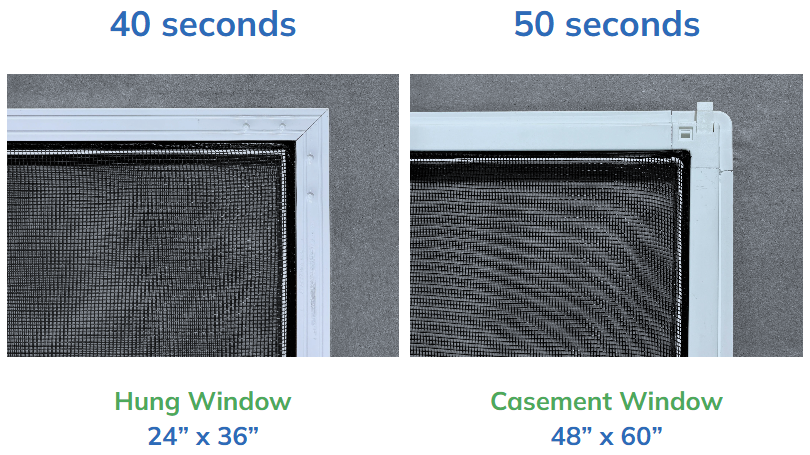

SAC-850 is best suited for household windows. like casement and hung windows, ranging up to 48” x 60”. If you need to produce patio doors or larger-format windows, the SAC-855 model is recommended.

What throughput can I expect from SAC-850?

SAC-850 is engineered for speed and efficiency, making it an ideal choice for manufacturers looking to maximize output without sacrificing quality. The automated machine processes a large window screen and spline insertion in about 60 seconds. For comparison, SAC-855 processes a full-size patio door in only 80 seconds.

Who is SAC-850 designed for?

SAC-850 is built for fenestration manufacturers who specialize in producing a high volume of household windows, but do not require the capacity to fabricate patio doors. If your business focuses on screen windows, such as casement, hung, or standard residential windows, SAC-850 is the ideal solution.

This machine is also particularly well-suited for:

Medium to Large Window Manufacturers: Companies that have outgrown manual screening methods and need to scale up production without investing in oversized equipment.

Operations Seeking Efficiency: Businesses aim to streamline their workflow, reduce labor costs, and minimize repetitive strain injuries among staff.

Manufacturers Focused on Standard Window Sizes: SAC-850 is optimized for household window dimensions, offering faster cycle times and greater throughput for these formats.

Firms Ready for Automation: Organizations looking to modernize their production line with reliable, easy-to-operate machinery that doesn’t require specialized training.

Will my company see labor or cost savings from SAC-850?

Yes. SAC-850, like other SAC machines, matches the speed of an experienced manual operator but offers several advantages:

No risk of repetitive stress injuries for operators

Consistent, repeatable quality—no “bad days” or distractions.

Reduces the need for multiple operators (one machine only needs one operator)

Minimizes downtime due to operator absence

Want to learn more about how automated manufacturing is solving the current workforce crisis? Read our latest article, “Bridging the Gap: How Automation Is Solving the Manufacturing Workforce Crisis,” to find out how.

Why should I invest in automation like SAC-850?

Automation is the future of manufacturing. SAC-850 (and the entire AUTOSCREEN process) is easy to operate and does not require specialist training. Automation also makes it easier to expand your production line with additional machines in the future.

Here’s why investing in automation makes sense:

Future-Proof Your Business: Labor shortages and rising operational costs are ongoing challenges in the fenestration industry. Automated solutions ensure consistent production even when staffing is unpredictable.

Ease of Operation: Unlike traditional manual screening, SAC-850 is designed for simplicity. It does not require specialist training; any team member can operate the machine with minimal onboarding, provided by Haffner’s technical staff.

Scalability: Automation creates a foundation for growth. Starting with SAC-850, companies can easily integrate additional machines—such as saws and assembly units—into a streamlined production cell.

Improved Productivity and Quality: Manual screening is labor-intensive and prone to errors. Automation ensures consistent results, higher throughput, and reduced downtime.

Competitive Advantage: Customers expect timely delivery and flawless quality. Automation helps you meet these expectations while positioning your business as an industry leader embracing innovation.

SAC-850 isn’t just a machine. It’s your production partner. By combining speed, accuracy, and reliability, it empowers manufacturers to overcome labor shortages, boost profitability, and deliver flawless screens every time. If you’re ready to take the next step in automation, the SAC-850 is engineered to meet the evolving needs of modern window manufacturers.

Haffner is continually innovating, with new materials and automation integrations in development. SAC-850 is part of a growing lineup, including saws and assembly machines, designed to streamline window production for manufacturers.

Explore more about SAC-850 and request a custom consultation today.